Integrated Testing of SKB EP Instruments

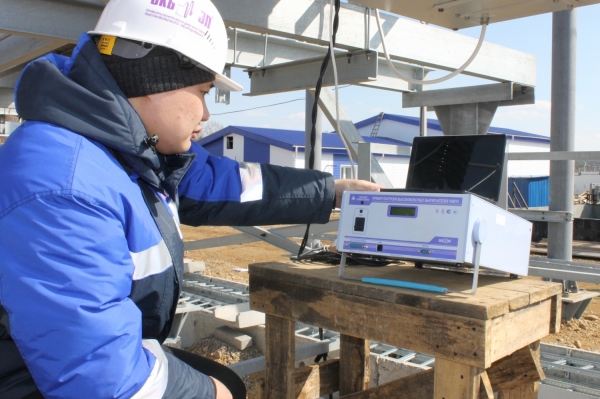

In early April, SKB EP specialists have conducted an integrated testing at 110/35/10 "Pivovariha" substation, where the following instruments have been used::

- instruments for control and testing of high-voltage circuit breakers;

- instruments for resistance measurement (microohmmeters and milliohmmeters);

- instruments for control of transformer OLTCs.

The instruments from the first group were tested at the vacuum circuit breaker (made by ABB). PKV/М7 and PKV/U3 instruments were used for control.

PKV/М7 is designed for in-place check of technical condition of the domestic and foreign high-voltage circuit breakers (oil, gas-insulated, vacuum and electromagnetic), with up to 4 breaks per pole, as well as of isolating and short-circuiting switches. The instrument measures time and speed characteristics and travel parameters, as well as current and voltage of circuit breaker solenoid drives.

PKV/М7 switch makes it possible to check the circuit breakers both in simple and complex switching cycles with solenoid currents up to 12A (direct and alternate) with setting of the required activation, deactivation, pause and off-delay pulse width.

PKV/U3 is designed for in-place check of technical condition of the domestic and foreign high-voltage circuit breakers of all types (oil, vacuum, gas-insulated and air) and all voltage classes from 10 kV to 1050 kV. Exercises control over the parameters of speed, travel and time characteristics of high-voltage circuit breakers with up to 20 breaks per pole. Using the instrument, it is possible to measure the solenoid currents and voltages and high current with the help of clamp meters. Available in two versions: PKV/U3.0 and PKV/U3.1.

The instrument has a built-in remote control for simple operations and complex cycles of circuit breakers for current up to 35 A, both for DC and AC drives.

MIKO-2.3 micromilliohmmeter has been tested on a high-voltage circuit breaker (made by ABB). MIKO-2.3 is a portable mini-lab, which can cover all resistance measurement tasks in electrical equipment, as it operates in four modes: microohmmeter, milliohmmeter, kiloohmmeter and thermometer.

MIKO-2.3 can rightly be considered the smallest microohmmeter for measuring the resistance with the highest current. With respect to these parameters, MIKO-2.3 is superior to all foreign and domestic microhmmeters. A foreign microohmmeter with closest characteristics at a current of 10÷500 A weights 7.5 kg and has a power supply. Weighting only 2.7 kg, MIKO-2.3 produces the current of 1000 A. High current burns oxide films, which are formed on the contacts and give a significant error when measuring resistance.

MIKO-7 and MIKO-8 were tested on TRDN-110 transformer (made by Togliatti Transformer, LLC).

MIKO-7 is designed for the measurement of transformer windings resistance (including OLTC) in the range of 1 microohm ÷10 kiloohm in engines, solenoids, cables and other circuits comprising inductance and resistance in the non-inductive circuits. The instrument is implemented in two software versions.

MIKO-8 measures DC resistance of windings in transformers, engines, solenoids, cables and other circuits comprising inductance and also electrical resistance in non-inductive circuits in the range of 10 microohm ÷10 kiloohm with current up to 10 A. The milliohmmeter has a mode of in-place diagnostics of OLTC condition without removing a contactor tank cover (DRM method).

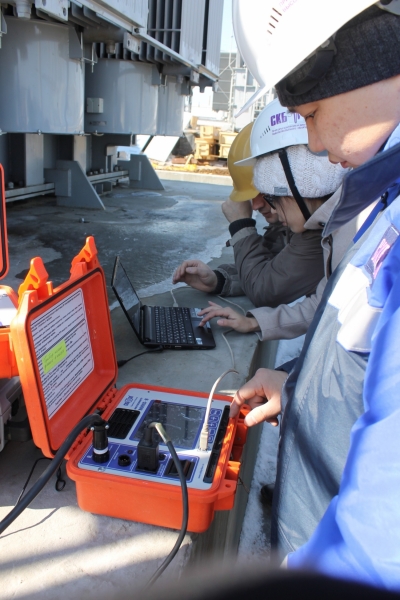

In addition, we have conducted tests on the new PKR-2М instrument, which inherited the advantages of predecessors and acquired new features. The works were carried out on TRDN-110 transformer with RS-9 OLTCs (made by Togliatti Transformer, LLC).

PKR-2М is designed for in-place check (DRM method) of technical condition of on-load tape chargers (OLTC) of all types, both resistor and reactor types.

On-place check of OLTCs allows for express-diagnostics of OLTC technical condition in all weather conditions. This check can not only determine the contactor switching time, but also carry out culling of OLTCs based on defective/non-defective criterion, which often permit specification of the defect nature, thus it is possible to make informed decisions on matters relating to the repair of these instruments.

For example, for RS, RNOA and other instruments, it is possible to determine the validity of operation of the main and arcing contacts, their condition (burned or good contact) and integrity of current-limiting resistors. For RNTA-35/320 instruments and their analogues, where the contactor and selector are replaced by the fine control switch, the main and arcing contacts, current-limiting resistor and the surface condition of all switch fixed contacts where moving contacts move, may be checked.

SKB EP company doesn’t stand still and tries to conduct its equipment and components as often as possible, both on the existing facilities and in the field, and on specialized test benches. The results allow creation of even more complete and intuitive training material for energetics specialists, which will work with the instruments of control and diagnostics of high-voltage circuit breakers and transformers.

Gaining experience, SKB EP is ready to share it with you, so if you want to study our instruments practically, you can always leave an application for an individual workshop on our website and the experts of our company will contact you.

Русский

Русский

Français

Français

Chinese

Chinese