Diagnostic of the "first stage" of voltage level regulation and power quality

In the last few years, requirements to electrical voltage level and power quality have been increasingly tightening. The problem is that the voltage in electrical network varies depending on load while for normal operation of the equipment it is necessary to find the supply voltage within the permissible range.

Most modern power transformers are equipped with means of adjusting, regulating, and correcting the mains voltage. This adjustment can be performed either under load, or only when the transformer is completely de-energized. Depending on significance of the object, and on how often these adjustments are needed, the NLTC ("no-load tap changer") or OLTC ("on-load tap changer") devices are used.

The voltage regulation of transformers using OLTC is carried out the same way as NLTC, but the number of winding taps, i.e. the number of adjustment stages is usually greater for OLTC and the control range is wider, and due to the presence of moving electromechanical elements, transformers with OLTC require 3-5 times more labour to control their state compared to uncontrolled devices. A malfunction in this device may lead to serious damage of the transformer as a whole meaning that power consumers will also suffer. According to statistics, almost 40% of transformer accidents occur due to critical damage to these devices, which is the second most common cause behind high-voltage bushings failures (according to Bengtsson Т., Kols H., Foata M., Leonard F. Monitoring tap-changer operations. CIGRE Report 12-209, 1998).

Just a few years ago and to this day, most enterprises practically did not use OLTC in automatic mode. Specialists prefer to decommission transformers, switch regulators and recommission them. However, this is quite impractical since the procedure is conducted only in case of sharp voltage drops. For example, under severe frost or heat when users start to run heaters or air conditioners on a massive scale.

This practice has a logical explanation: OLTCs have a significantly lower resource and reliability than the transformer itself, and power engineers do not want to jeopardize the entire equipment. Firstly, it is very expensive, and secondly certain knowledge and experience are needed for diagnostics, troubleshooting, and repair, but just a few specialists obtain the knowledge.

As such, the OLTC diagnostics is conducted very rarely, or is totally excluded, since enterprises often lack the necessary equipment, and now it is very difficult and unreliable to check regulators by rule of thumb. For example, traditional method for circular diagram recording provides for aural determination of operation of the switching device contacts by operator while closing and opening of the circuit breaker contacts is visually determined by lighting and extinguishing the signal lamps.

But over the past few years, increasingly stringent requirements have been adopted for the electrical voltage level and power quality, which means that modern portable diagnostic tools are emerging with the help of which it is possible to check the compliance of OLTCs with specified characteristics and identify emerging defects at an early stage.

SKB EP addressed OLTC diagnostics back in 2007, when the first model of the PKR-1 diagnostic device entered the market, which proved itself perfectly, collected quite a few positive reviews, and offered an opportunity for easy, quick and accurate OLTC diagnostics to their users. After 4 years (2011) based on user recommendations, the device was improved and refined to the PKR-2 model, and in 2014 another modification of the PKR-2M was created.

Today, two devices are available to check the technical condition of resistor and reactor type OLTC of transformers within the SKB EP range: PKR-2 and PKR-2M, the fundamental function of which is the ability to record oscillograms of contactors and record circular diagrams simultaneously in all phases. These devices allow you to detect such malfunctions and parameters of OLTCs as:

- drive jamming,

- determine the condition of current-limiting resistors (integrity),

- deterioration of the contactor contact connection quality,

- times of the contactor switching stages,

- switching time difference by phases,

- loose or weakened connections etc.

Both devices are designed for demountable diagnostic when the device tank is opened as well as partial or complete drain of transformer oil, but at the same time they greatly facilitate such control as they are equipped with special remote probes to simplify the process of connecting to the contactor contacts. Here it is worth noting that for many years the design of probes has not changed, because high-voltage stock was equipped with OLTCs of certain common brands and customers did not face other needs, but the manufacturer forges ahead and responds to recommendations and requests of its customers, so new ergonomic probes were developed and implemented, which differ from the existing ones. The first batch is already under operation of the customer.

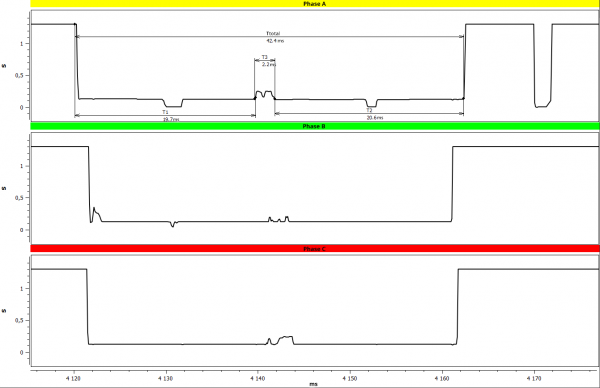

Oscillogram of the OLTC operation by three phases – direct demountable diagnostic (results from the OLTC PC software)

Presently, OLTC demountable diagnostic is the most common procedure in system of the electric power industry, for which it is necessary to demount the device, but such a procedure has serious limitations for example, it is impossible under high humidity and negative ambient temperature and as a rule, these labor-intensive processes are carried out in summer under good weather.

In addition, it is worth noting that the equipment demounting is a category of major repairs, but there is no need to carry out repairs without preliminary diagnostic if this often leads to a waste of money and reduces its reliability. A much more effective solution would be to carry out a diagnosis by determining whether the repair of the OLTC and other transformer components is needed using procedure without demounting.

Therefore, PKR-2M device differs from the PKR-2 model is a non-demountable check of the state of the resistor type OLTC without removing the contactor tank cover using the DRM method (Dynamic Resistance Measurement test).

As a result of such diagnostic, a graph of the measured resistance is plotted when switching taps to enable not only rejection according to the serviceable/faulty criterion, but often also to indicate the defect nature, which at least makes it possible to exclude unnecessary openings and checking of serviceable OLTCs.

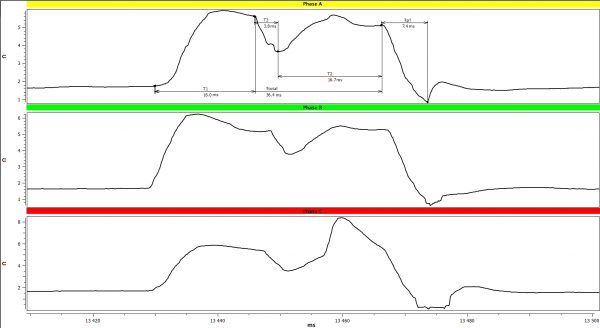

Oscillogram of the OLTC operation by three phases – DRM non-demountable diagnostic (results from the OLTC PC software)

Non-demountable check requires minimal labour, so it is recommended to perform such a diagnosis during any planned and unscheduled inspection of power transformer. And due to the fact that hardware implementation of DRM-method in the PKR-2M (unlike similar equipment) is significantly improved, the resulting oscillogram actually approached the results that can be obtained only when directly connected to the contactor contacts.

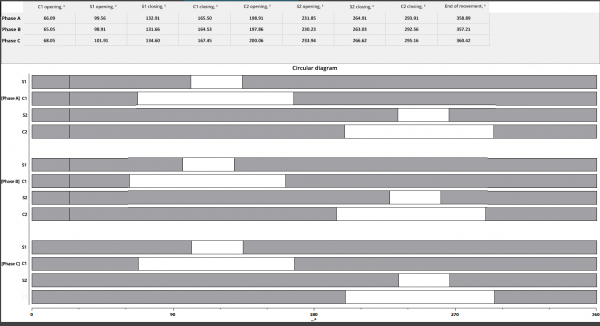

To record circular diagrams, devices are equipped with the angular movement transducer, which is installed on the drive shaft protrusion and its coupling with shafts of various drives is provided by set of special individual axes and bushings. At the same time, installation of the transducer, axles and bushings is made easily, by simply putting on the shaft protrusion without using any tool even if there are defects on it in the form of curvature, notches and burrs.

Circular diagram of the OLTC operation by three phases (results from the OLTC PC software)

When choosing SKB EP devices, you rely on the quality and uniqueness of developments proved by time and feedbacks from large industrial enterprises. In addition, SKB EP provides a continuous technical support to its Customers and conducts on-site training sessions.

The use of PKR devices will significantly reduce the financial and resource costs of the organization, as well as improve quality of the transformer diagnostic and avoid unplanned repairs of facilities. OLTCs should be used for their intended purpose and please do not hesitate operating them in automatic mode, because their diagnostic can be simple, understandable and accessible if you choose modern equipment, pass a training course and gain some experience.

If you are interested in the PKR-2 and PKR-2M devices and you want to know all the functionality and capabilities of the devices-please visit the website: www.skbep.com, send e-mail to: skb@skbep.com or call: +7 (812) 500-25-48.

SKB EP blog is available on instagram (account @skbep_com) where the manufacturer shares information about the devices in the framework of practical tests as well as details of their operation. Sign up!

Русский

Русский

English

English

Français

Français